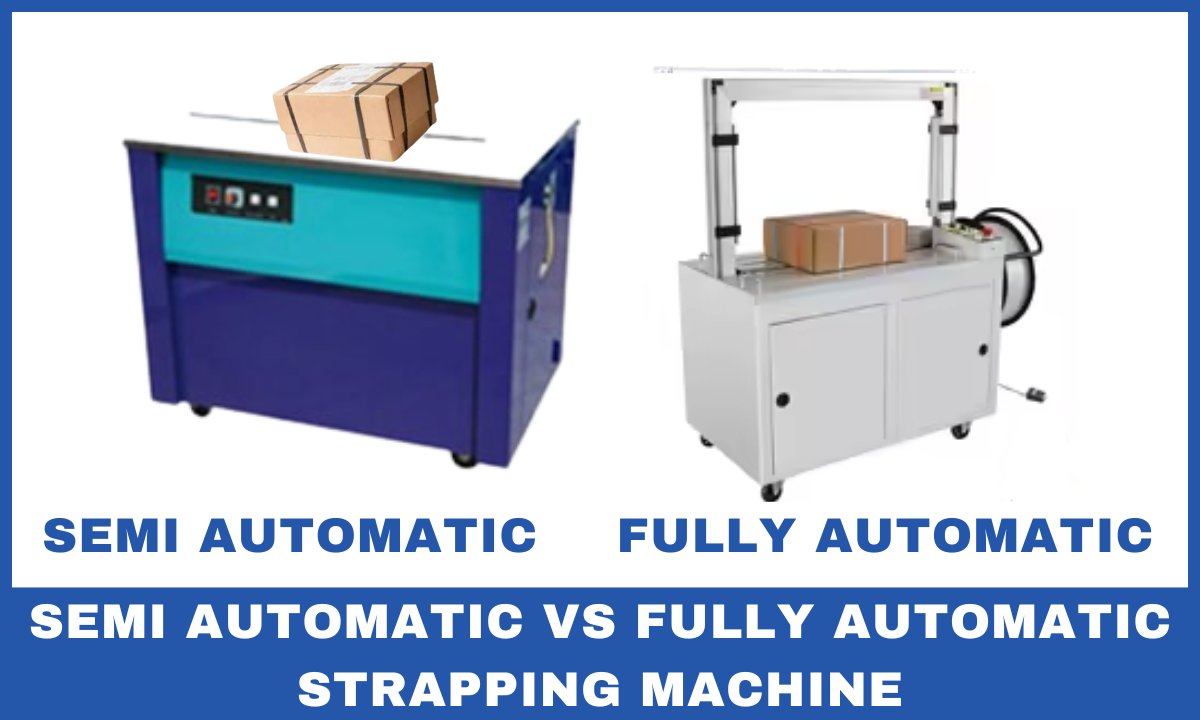

In packaging industry the choice between semi-automatic and fully-automatic strapping machines can significantly impact operations. These machines play a crucial role in securing packages with straps, but the level of automation they offer varies remarkably. Following are the difference between semi-automatic and fully-automatic strapping machines.

Semi-Automatic Strapping Machines:

Semi-automatic strapping machines serves as a bridge between manual and fully automated processes. They offer a degree of automation while still requiring some manual intervention from operators. Here’s how they work:

1. Manual Loading: In a semi-automatic machine, the operator manually places the item to be strapped onto the machine's platform. This step involves positioning the package and ensuring it is properly aligned for strapping.

2. Manual Strap Feeding: Once the package is in place, the operator manually feeds the strap around the package. This step requires the operator to guide the strap through the machine's tensioning and sealing mechanisms.

3. Automatic Tensioning, Sealing, and Cutting: After the strap is in position, the operator activates the machine, triggering the automatic tensioning, sealing, and cutting of the strap. The machine completes these tasks without further manual intervention.

Semi-automatic strapping machines are well-suited for applications where flexibility and manual control are valued. They are often used in lower-volume operations or settings where the packaging requirements vary widely.

Fully-Automatic Strapping Machines:

A fully-automatic strapping machine offers a higher level of automation, minimizing manual intervention and maximizing efficiency. Here’s how they operate:

1. Automated Loading: In a fully automatic machine, sensors detect the arrival of the package on the machine's platform. The machine then automatically positions the package for strapping, eliminating the need for manual loading by operators.

2. Automatic Strap Feeding: Once the package is in position, the machine automatically feeds the strap around the package. Advanced mechanisms ensure precise positioning and tensioning of the strap without operator input.

3. Hands-Free Operation: The entire strapping process, including tensioning, sealing, and cutting the strap, is performed automatically by the machine. Operators are free to attend to other tasks while the machine completes the strapping process.

Fully automatic strapping machines are ideal for high-volume operations where speed, consistency, and efficiency are important. They are often integrated into conveyor systems or packaging lines for seamless automation.

Choose the right machine as per your requirement

When considering whether to invest in a semi-automatic or fully automatic strapping machine, it’s essential to evaluate your specific requirements and operational constraints. Factors such as production volume, packaging complexity, and budget will influence your decision.

For businesses with lower-volume operations or those that prioritize flexibility and manual control, a semi-automatic strapping machine may be the ideal choice. However, for high-volume operations that demand speed, consistency, and hands-free operation, a fully automatic strapping machine offers unparalleled efficiency and productivity.

By understanding the differences between semi-automatic and fully automatic strapping machines, businesses can make informed decisions that optimize their packaging processes and drive success in today's competitive market.