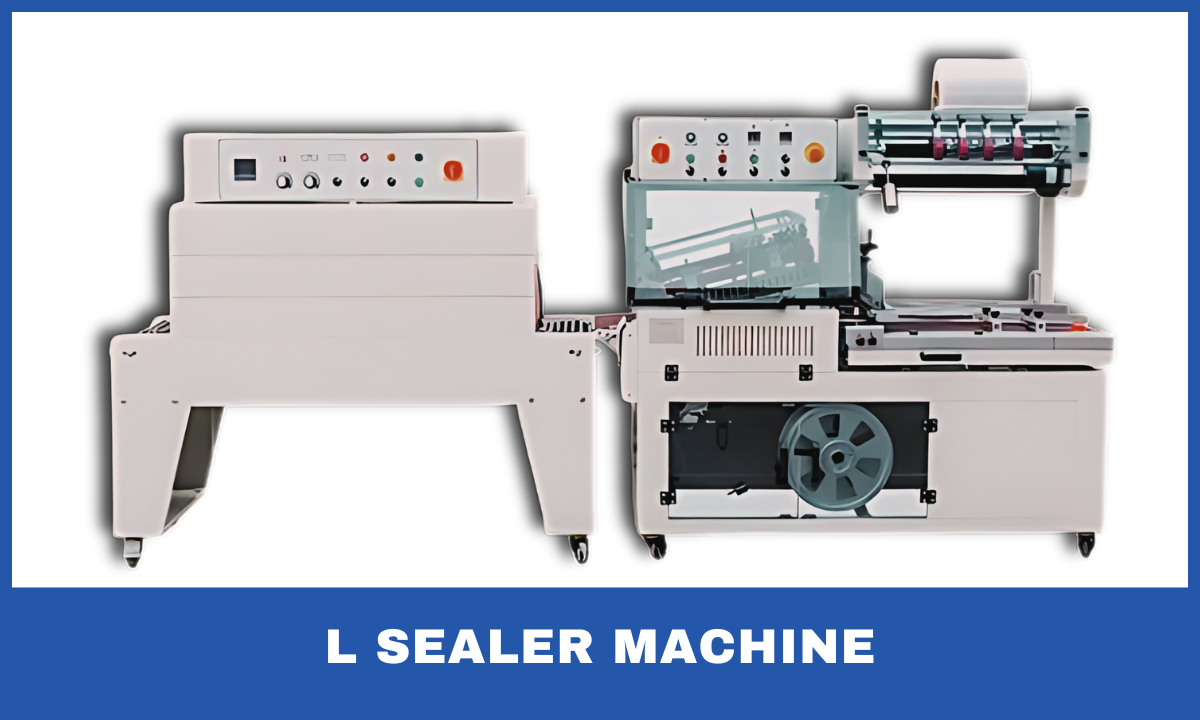

When it comes to packaging machines, accuracy is the most important factor. The L-sealer machine is a versatile and efficient equipment that plays a vital role in achieving perfect packaging. So let us begin with what exactly an L-sealer machine is?

What is an L-Sealer Machine?

An L sealer machine is special type of packaging machine which wrap the product by shrinking plastic(handles from roll) film. The name of the machine itself is derived from L-shaped sealing bar which cuts and seals the film around product. But still you have to transfer the package to pass through a heat tunnel where it will seal tightly around your product.

Key Features of L-Sealer Machines:

Versatility: Suitable for a wide range of products, from small items like DVDs to larger ones such as boxes.

Efficiency: Sealing is speedy and even boosting productivity.

Professional Packaging: This gives you a neat and professional appearance which improves the presentation of the product.

Types of L-Sealer Machines

There are several types of L-sealer machines, each catering to different packaging needs and operational scales. Here are the main types:

Manual L-Sealers:

Operation: The film and product must be manually placed in position by hand.

Ideal For: Small scale operations or businesses with lower to moderate levels of packaging requirements.

Semi-Automatic L-Sealers:

Operation: Products must be put into place manually while sealing and cutting are automated functions.

Ideal For: Medium-sized businesses looking to balance cost and efficiency.

Automatic L-Sealers:

Operation: This process is completely automated; it includes placing the product, sealing it, and cutting out the film.

Ideal For: Large-scale operations that require high throughput rates.

How do L-Sealer Machines Work

L sealer machines are built up of different steps:

Product Placement. A product is placed on the machine`s conveyor belt or platform.

Film Wrapping. Shrink film wraps itself around the product, covering it fully.

Sealing and Cutting. The film is cut into a loose wrap around the product by the L-shaped sealing bar.

Heat Shrinking. Then, the sealed pack goes through a heat tunnel. The heat makes this package tightly shrink to conform to its shape, leaving no room for anything else except that item only.

Applications of L-Sealer Machines

- Due to their versatility and efficiency, L-sealer machines have found application in many sectors. Some prevalent uses are as follows:

- Retail: They package consumer products like books, DVDs and cosmetics for display in supermarkets stores among other sellers.

- Food and Beverages: To ensure freshness and tamper evidence of foodstuffs such as bakery items, confectionery or drinks they are packed with shrink films.

- Pharmaceuticals: Medical supplies and pharmaceutical products are secured using tamper-evident packaging techniques here.

- Manufacturing: Protection and distribution are the reasons why spare parts, tools, industrial materials etc get packed this way at factories.

- e-Commerce: That offer secure, professional packaging for online sold goods thereby ensuring safe delivery to customers at destination.